Systems installation for

Distribution and Power Generation

Seaport Installations,

Operational Control Center

Building Systems facility for

distribution, generation and power control

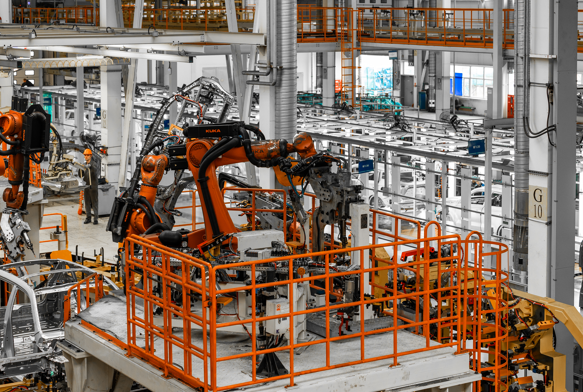

Facilities in Stamping, Bodywork,

Painting and Assembly

industrial process automation

and commissioning of facilities

Systems installation for

Distribution and Power Generation

Seaport Installations,

Operational Control Center

Building Systems facility for

distribution, generation

and power control

Facilities in Stamping, Bodywork,

Painting and Assembly

industrial process automation

and commissioning of facilities

Career Summary

In 1980, I started my activities in the industrial area, at the command teams for construction and assembly in the steel industry. In 1982 my work was published in the newspaper after the completion of 288,000 m2 of industrial area surrounding the hot strip mill (HSM), plates furnaces, annealing plates, control rooms, medium and high voltage substations. In 1990, my professional career in the field.

Engineering

Activities: Responsible for the physical-financial schedules with contingency actions for the critical paths of the projects ensuring the results, establishing engineering actions and resources needed to meet the goals. Ensure that the solution in the FEL 2 phase does not require significant engineering modifications that impact time and CAPEX in the FEL 3 and deployment stages. Project management, commissioning installation of generation, distribution and energy efficiency systems integrated with SCADA supervisors and artificial intelligence algorithms. Responsible for the maintenance of projects, operating costs (OPEX), financial results and profitability of contracts.

Energy Efficiency

Substations

Energy

Construction and maintenance of Data Center involving project with Uptime certification, installation of 5 generators 2,5MVA -13,8kV, infrastructure for power distribution in medium voltage with 85000 meters of cables, 8 PDU-Power Distribution Units of 300kVA, 10 RPP-Remote Power Panel 225KVA, 3-ATS Automatic Transfer Switches 800kVA, 4 UPS-Uninterruptible Power Supply to 400KVA, control of installations with EPMS-Electrical Power Management Systems, IEC 61850 network in medium voltage substations for protection and rejection of electric charges on demand, BMS-Building Management System integrated with CCTV, access control, perimeter security, HVAC system with 5 chillers of 500 TR capacity each, 88 fan coils distributed on floors and interconnected with 38 tons of pipe SCH 40,1550 meters air conditioning ducts, 1340 tons of steel structure, system for diesel supply 120000 liters, firefighting system and early detection type HSSD with FM-200, 19380 ft² of acoustic treatment and noise attenuators, electrical system selectivity, commissioning of systems and integrated testing of the facility.

Energy

Construction and maintenance of Data Center involving project with Uptime certification, installation of 5 generators 2,5MVA -13,8kV, infrastructure for power distribution in medium voltage with 85000 meters of cables, 8 PDU-Power Distribution Units of 300kVA, 10 RPP-Remote Power Panel 225KVA, 3-ATS Automatic Transfer Switches 800kVA, 4 UPS-Uninterruptible Power Supply to 400KVA, control of installations with EPMS-Electrical Power Management Systems, IEC 61850 network in medium voltage substations for protection and rejection of electric charges on demand, BMS-Building Management System integrated with CCTV, access control, perimeter security, HVAC system with 5 chillers of 500 TR capacity each, 88 fan coils distributed on floors and interconnected with 38 tons of pipe SCH 40,1550 meters air conditioning ducts, 1340 tons of steel structure, system for diesel supply 120000 liters, firefighting system and early detection type HSSD with FM-200, 19380 ft² of acoustic treatment and noise attenuators, electrical system selectivity, commissioning of systems and integrated testing of the facility.

Facility Management

Facility Management

Maintenance five industries with a total area of 2,650,000 square meters involving a major power substation with 100 MVA, 138 kV / 13.8 kV, administrative buildings with total area of 414,000 square meters, 18 production lines, utilities center with two turbines steam and four air compressors with 12 ton per hour capacity, 38 reinforced substation (SF6), one wastewater treatment plant with 12 m3 / h capacity, data center with an area of 280 square meters, lighting, systems drainage;

Research

Reserch

Installation and commissioning of corporate building involving power system with 5 medium voltage substations with 12,225 kVA electrical power, diesel power generation with 3,500 kVA electric power, 4,500 m busway with 4,000 Amperes, 1,550 kVA in Uninterruptible Power Supplies (UPS) , 240 kW in rectifiers in direct current, control room with 8 workstations connected BMS servers and servers for IEC 61850, 1,350 kVAr of capacitor banks for power factor correction, 4 active harmonic filters, IEC 61850 network for the substations with 89 Intelligent Electronic Device (IED), 29,487 points of automation in the BMS – Building Management System integrated to 1,580 controllers distributed in the systems of power management, utilities, emergency sonorization, detection and fire alarm, central air conditioning control Cold water – comfort and data center.

Publications & Conferences

Controlled Systems over the Internet

International Congress Automation

Description: published work on the installation of equipment, communication networks and configuration of protocols for automation systems over the Internet

Artificial Neural Network Application to a Building Hybrid Illumination System

IEEE International Symposium on Industrial Electronics

Description: control algorithm using neural networks for energy efficiency of the building

Process Automation in Rolling Hot Strip

Newspapers

Description: Installation of control rooms, process instrumentation, communication networks, dedicated servers and remote control units.

This is my life

Certificate Programs

FEL – Front End Loading & Gated Systems Installation and Programming of Industrial Robots

Capital Projects

Expansion of facilities to increase capacity in TEUs of containers stacking yard and integrating CCO-Operational Control Center

Energy

Design, planning, installation and system commissioning for a cogeneration plan with 4 turbo generators to 18 MW of power steam each (110t /h – 95 bar and 460 °C), demineralisation unit for water treatment